Mortise and tenon joints appear deceptively simple, but are actually quite demanding to do well. The amateur is unlikely to saw as well as the apprentice trained professional of the past. The hand cutting of mortises is shown in detail as well as a quick look at a hollow chisel mortising machine. David explores techniques for producing accurate tenon cheeks. These are needed for good glue joints. This precise work is achieved with the aid of the No. 71 router plane. The video covers small draw bore mortise & tenon joints, and wedged through tenons, which are often a feature of Arts & Crafts work. Mitred through tenons and table leg mortises are also shown.

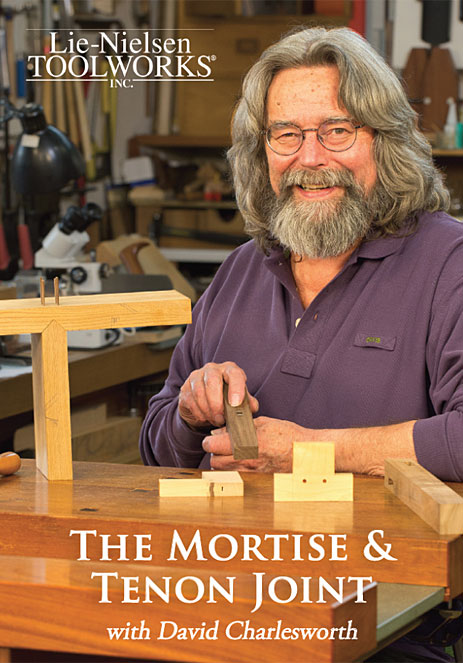

David Charlesworth has taught woodworking since 1973 and is widely respected in England as a writer for Furniture & Cabinetmaking Magazine. His specialty is getting the most out of hand tools in precise and original ways.

Chapters

1. Mortise Chisels

2. Sharpening Mortise Chisels

3. A Handy Guide for Sharpening

4. Grinding Mortise Chisels

5. The Drawing

6. Marking Gauges

7. Marking the Mortise

8. Hammers and Bob Wearing’s Mortise Cutting Technique

9. Mortise Depth and Cutting the Mortise

10. Testing the Mortise & Making a Tenon Test Stick

11. Marking the Tenon

12. Sawing the Shoulders

13. The Router Plane & How to Sharpen it

14. Trimming the Tenons to Thickness

15. Cutting the Tenon to Width & Trimming the Shoulders

16. Using the Pyramid Blocks in the Clamping Process & Avoiding Glue Squeeze Out

17. A Quick Look

18. A Variation on Mortise & Tenon Joint

19. Making the Pegs

20. Planning the Holes in the Mortise Piece

21. Inserting the Pegs

22. Making the Surfaces Flush

23. Planning the Joint

24. Hollow Chisel Mortiser

25. Mitred Tenons

26. The Wedges

27. Glue Up

28. A Chinese Variation on Design

29. Conclusion

176 minutes, Lie-Nielsen Toolworks Productions, 2018. Video download.

Reviews

There are no reviews yet.